WASTEMASTER TSB 2-3 Combined Septage Receiving Stations

Up to three processes in one machine

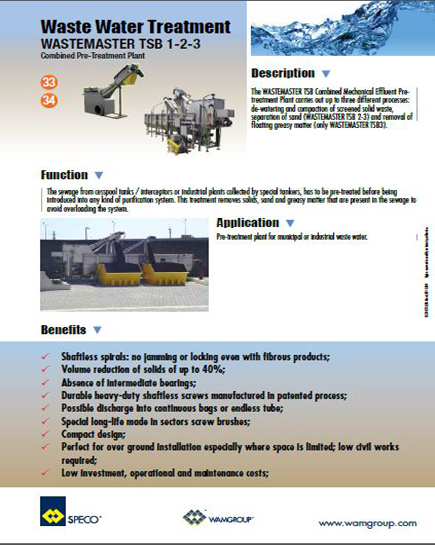

WASTEMASTER TSB2/3 efficiently carries out up to three different processes: de-watering and compacting of screened solid waste, separation of sand and removal of floating greasy matter.

The WASTEMASTER TSB 2/3 carries out up to three different processes: de-watering and compacting of screened solid waste, separation of sand and removal of floating, greasy matter.

Function :

- Sewage from septic tanks / cesspools / interceptors or industrial plants collected by special purge tankers has to be pre-treated before being introduced into any kind of purification system.

- The process consists of the removal of solids, sand/grit and greasy matter which are all present in the sewage in order to avoid overloading of the treatment plant.

Features :

- Flow rates of up to 30 litres per second (63.5 cfm)

- Inlet screen mesh: 5, 6, 7 mm

- Sand separation with TSB-2/3: 90% particle size ≥ 200 μm

- Grease removal with TSB-3

- Up to 35% solids volume reduction

- Modular design

Benefits :

- No jamming or locking even with fibrous products thanks to shaftless spirals

- Volume reduction of solids of up to 40%

- Absence of internal bearings

- Low r.p.m.

- Possible discharge into plastic bags

- Special long-life screw brushes

- Compact design

- Perfect for over-ground installation especially where space is limited; no civil works required

- Low investment and maintenance costs

-

Combined Septage Receiving Stations

WASTEMASTER TSB 2-3